The fashion system is a $2.4 trillion industry, with more than 60 million people involved and listed as one of the most polluting systems in the world. The industry accounts for 8% of greenhouse gas emissions, 20% of industrial water pollution globally and workers face issues such as hazardous environment and low wages. These data figure out clearly how big the impact of this industry on the environment is. However, this is not just about the production of sustainable materials.

The Green Report

What really means being sustainable

In addition to fabric-based improvements, the fashion industry is re-thinking the whole supply chain. The manufacturing stage, along with some dyeing and finishing are trying to relocate when it is possible. Social factors are the main issue abroad with labor and health and safety standards having been in public spotlight recently. Bur also the CO2 footprint of transportation is very high.

Packaging as well, has clear impacts related to sustainability. In fact, as food industry is doing, fashion companies are developing greener packaging, introducing compostable and recyclable materials.

With resources becoming even scarcer, the industry will face rising costs from labor to materials and energy. Based on conservative projections, fashion brands’ profitability levels are at risk in the range of at least 3 percentage points if they don’t act determinedly, and soon. The facts show a clear need for acting differently. The good news is that by changing practices, the industry can both stop the negative impact and generate a high amount of value for society, while also protecting profitability.

The fashion industry has a clear opportunity to act differently, pursuing profit and growth while also creating new value for society and therefore for the world economy. It comes with an urgent need to place environmental, social, and ethical improvements on management’s agenda.

The best performers on sustainability are the very big players as well as some mid-sized, family owned companies, while over half of the market, mainly small to medium-sized players, has shown little effort so far. Sportswear is scoring records on sustainability. The rest of the industry is somewhere in between.

Brands have to find innovative ways of doing business and efficient production techniques that minimize the use of water, energy, and land, as well as hazardous chemicals. By realizing better working conditions and improving workers’ safety, they will minimize their operational and reputational risks and create significant value for themselves and the world economy.

Behind the labels- The most called sustainable brands

The road to becoming totally green is long and windy, but many brands are striving to become more sustainable. This issue is fundamental for the success of a brand today, from mass market to luxury. Being sustainable is no longer a priority for some niche brands because the environment is a sensitive subject for everyone. The topic is not only for committed young people and ecologists, it has become a trend. Millennials associate the idea of Eco-fashion with cool and trendy. Despite the fact that fast-fashion is considered the first enemy of green, due to its low cost and large quantity production, it is precisely from the mass market that positive examples of sustainability are coming in.

The pollution of the fashion industry comes to 60% from the production of the raw material. In fact, knowing well the materials that are used and optimizing their production from an ecological point of view, today is a duty for every brand. But, as we well know, brands do not directly control their entire supply chain, so to be considered sustainable, they have to give transparency to their entire production network and also trace back to their suppliers’ suppliers. They must have control of the raw material, but also of the manufacturing process and ensure the well-being of their workers and the workers of their suppliers. After what happened in Banghladesh, in the H&M factories, brands have become aware that producing at low cost and without control, can have harmful impacts, even extreme social ones. So the manufacturing, besides saving as much energy as possible, is also rethought in its location in order to bring production closer to the selling points and reduce time, costs and the source of pollution due to transport. In fact, 40% of fashion pollution is due to transport.

Can a fully sustainable fashion brand actually exist? It depends on your definition of “sustainability” and the challenges that accompany it: water pollution, CO2 emissions from soils, the use of natural resources…unfortunately, there’s no single solution for all these problems. Any kind of production has an impact on the planet, including that performed by the fashion industry. Sustainable fashion involves weighing the pros and cons and coming up with the best possible solutions.

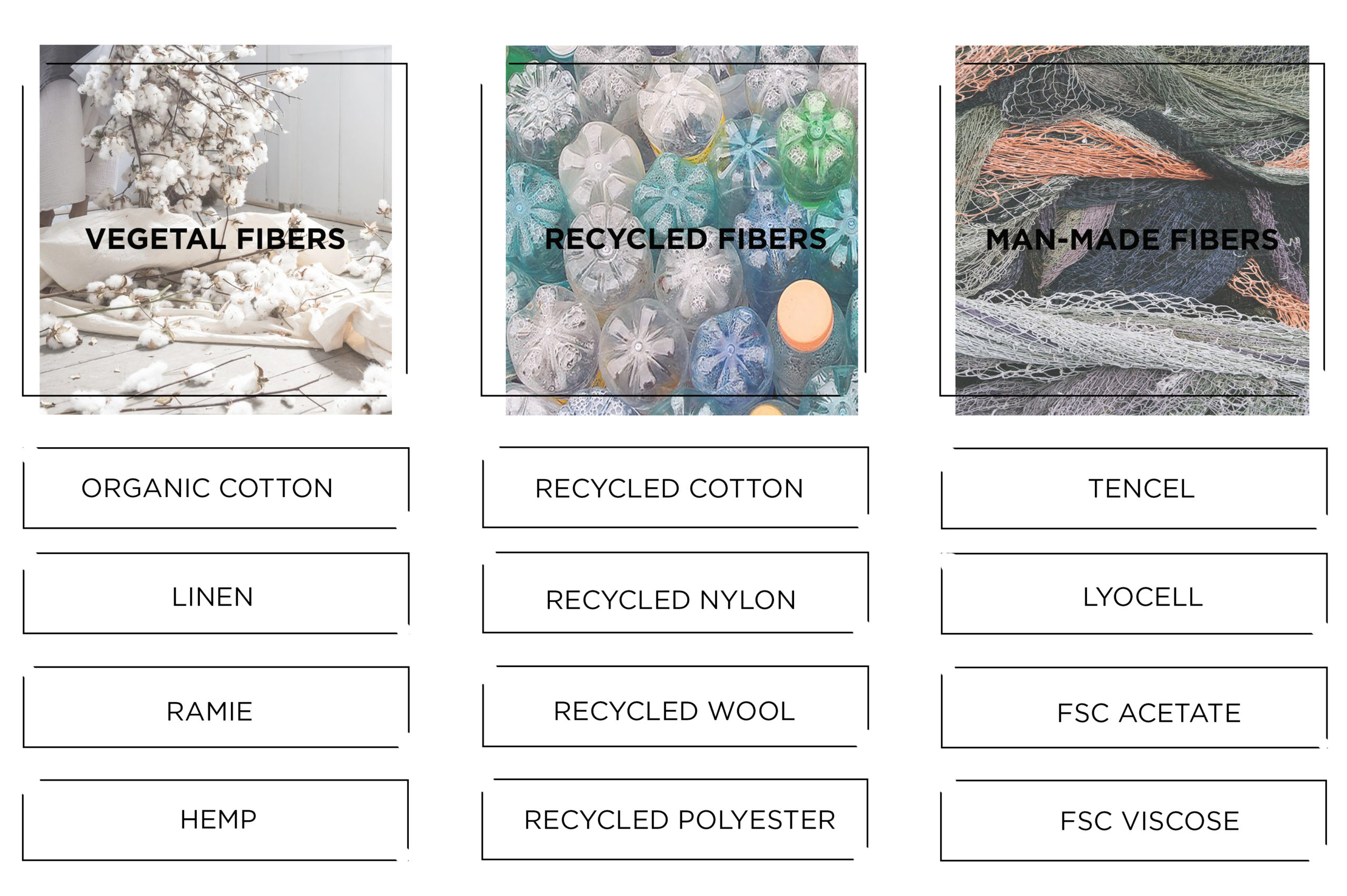

What you need to know about the most common fibers and materials

The raw materials have disproportionately large impact on sustainability, partly because of the effect it has on recyclability. Data from the Higg Materials Sustainability Index (MSI), shows, unexpectedly by what we might believe, that leather and natural fibers (silk, cotton, wool) have the overall highest environmental impact. These materials show the highest negative impacts across all dimensions. Water, land and pesticides use for cotton have a great impact on environment, while incorporating recycled polyester reduces a garment’s energy footprint.

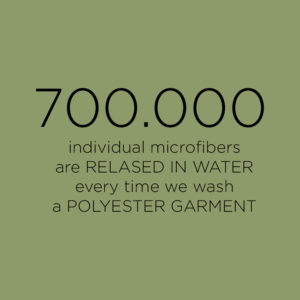

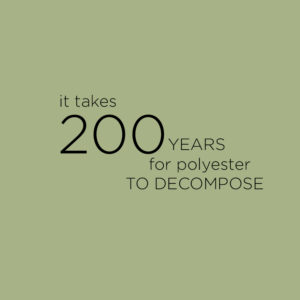

Polyester and other synthetic fabrics are cheap and versatile materials but they aren’t biodegradable. Furthermore, when washing synthetic fabrics like polyester, acrylic and nylon, thousands of plastic microfibers are released down the drain of your washing machine. These microplastic fibers are so small that they pass through the sewage treatment works and make their way to the rivers and then the oceans. They tend to accumulate and act like sponges, soaking up all the toxic elements around them. Many fishes and other animals swallow them, and if we eat those animals, we eat plastic too.

The processing phase of fibers including spinning, weaving, and other preparation of fabrics, are all activities with substantial environmental footprints. Dyeing fabrics alone can require as much as 150 liters of water per kilogram, and the water is often discharged unfiltered into waterways. Wastewater pollution can be considered as a major area of challenges within processing but also in raw materials stages due to the use of nutrients and fertilizers.

Cotton is mainly produced in dry and warm regions, but it needs a lot of water to grow. In some places, like India, inefficient water use means that up to 20,000 liters of water are needed to produce 1kg of cotton. In the meantime, 100 million people in India do not have access to drinking water.

99.3% of cotton is grown using fertilizers and genetically modified seeds. Cotton represents 10% of the pesticides and 25% of the insecticides used globally.99% of the world’s cotton farmers are located in developing countries where labor, health and safety regulations are nonexistent or not enforced most of the time. Child and forced labor are common practice.

Wool has several sustainable attributes: it is rapidly renewable, biodegradable, recyclable, and can be produced organically, but it also has its downsides.

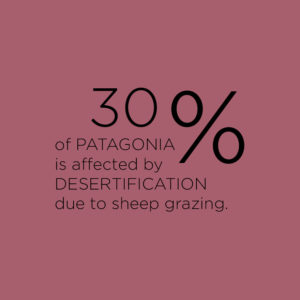

As with other forms of animal agriculture, raising sheep for wool gobbles up precious resources. Land is cleared and trees are cut down to make room for grazing, leading to increased soil salinity and erosion and a decrease in biodiversity.

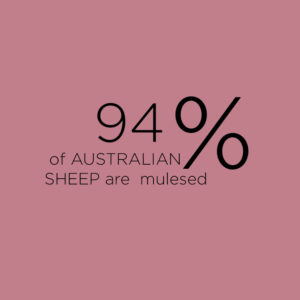

Manure generated by farmed animals, in countries like Australia and New Zealand, where vast flocks of sheep have been expanded to meet the world’s demand for wool has significantly contributed to the increase in atmospheric greenhouse gases over the last 250 years. Not to mention animal cruelty especially during shearing.

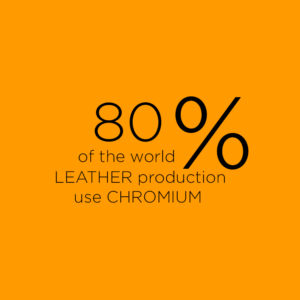

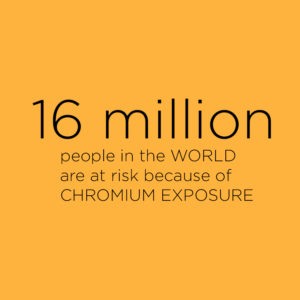

The use of leather is therefore controversial from an ethical, ecological and social point of view. At the moment, research is focused on reducing and eliminating heavy chemicals, and finding alternatives to animal skin. Environmental and social concerns related to leather are mostly linked to the tanning process. Toxic chemicals are used (chromium in 80% of cases) to transform the skins into wearable leather. Animal cruelty is another topic very criticized for leather use. But most “faux leathers” are made of plastic, specifically polyurethane, PVC or polyester, all non-biodegradable materials made of fossil fuels. In addition, leather is a durable material and most of the leathers are a by product of the meat industry.

Environmental and social concerns related to leather are mostly linked to the tanning process: Toxic chemicals are used (chromium in 80% of cases) to transform the skins into wearable leather.

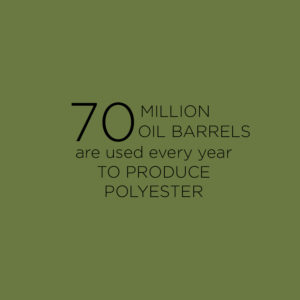

Polyester is the most common fiber in our garment. We can find it in 52% of our clothes. Polyester is a synthetic petroleum-based fiber, and is therefore made from a carbon-intensive non-renewable resource. The production of polyester uses harmful chemicals, including carcinogens, and if emitted to water and air untreated, can cause significant environmental damage. Polyester contributes to ocean pollution due to the microfibers rejected by the garments once washed in the washing machine. About 35% of the micro-plastics present in the ocean comes from synthetic fabrics.

One of the most positive aspects of polyester is that it is completely recyclable, and it is also possible to manufacture polyester from recycled plastics.

Sustainable fabrics and materials

Organic cotton

Organic cotton is produced and certified to organic agricultural standards, without the use of toxic pesticides and fertilizers or genetically modified organisms that damage the soil, ecosystems, and humans. The farming methods improve the lives of cotton farmers and make their work environment healthier.

Linen, Hemp & Ramie

Linen is a natural fiber that stems from the flax plant. It uses considerably fewer resources than cotton or polyester (such as water, energy, pesticides, insecticides, fertilizers). Flax can grow in poor soil which is not used for food production. In some cases, it can even rehabilitate polluted soil. Flax plants also have a high rate of carbon absorption. For these reasons, linen can be considered a sustainable material, even when it is not organically grown.

Hemp is one of the fastest-growing plants and it doesn’t need much water, energy, pesticide, or fertilizers. The plant is very good for the soil, it can be grown for many years in the same place without exhausting it. It produces 2 times more fiber and requires 50% less water than cotton. This is why hemp is considered to be eco-friendly. Hemp has similar properties to linen. Ramie is very similar those to fiber but less common.

Recycled cotton

Recycled cotton requires far fewer resources than conventional or organic cotton and 750 000 liters of water can be saved using this fiber.

Cotton can be recycled using old garments or textile leftovers. The quality of the cotton may be lower than of new cotton. Recycled cotton is therefore usually blended with new cotton. The production of recycled cotton is still very limited.

Recycled nylon

Recycled Nylon has the same benefits as recycled polyester: It diverts waste from landfills and its production uses much fewer resources than virgin nylon (including water, energy, and fossil fuel). A large part of the recycled nylon produced comes from old fishing nets. This is a great solution to divert garbage from the ocean. It also comes from nylon carpets, tights, etc. Recycling nylon is still more expensive than new nylon, but it has many environmental advantages.Econyl® is one good example of a certified, eco-friendly, recycled nylon textile.

Recycled polyester

The most common source of raw materials for recycled polyester comes from old PET bottles or raw material waste from the manufacturing industry. Either way, the process saves water and energy (-70%), and produces up to 50% less CO2 emissions, compared to conventional generic polyester.

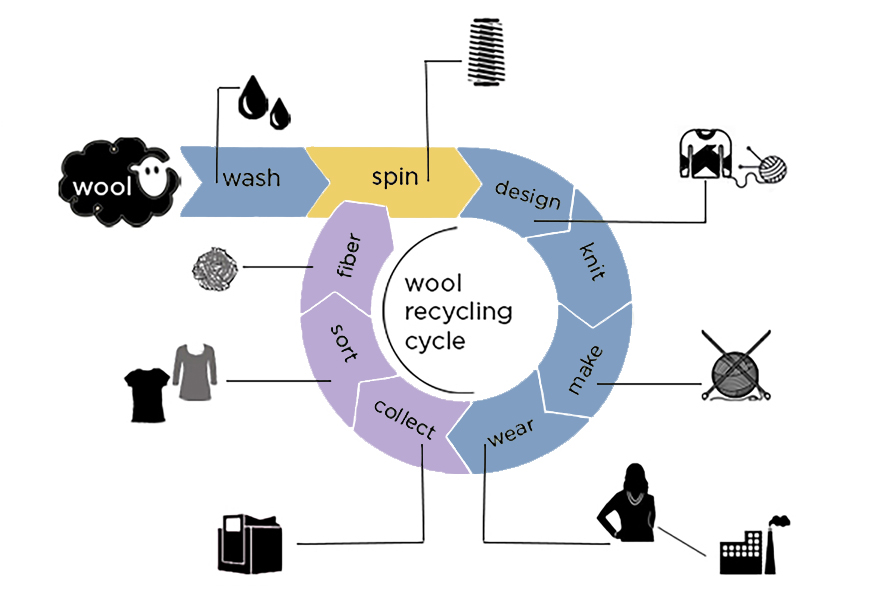

Recycled wool

This material is well known for such a long time and it is made from scraps from other wolly manufacturing. Apart from diverting used wool garments from landfills, it saves a considerable amount of water, reduces land use for sheep grazing, and avoids the use of chemicals for dyeing. In Italy, Prato is famous to be the leading producer of recycled wool.

Lyocell and Tencel ™

Lyocell and TENCEL™ Lyocell fibers are made from wood pulp, primarily from the eucalyptus tree and from certified and controlled forests. The fast-growing eucalyptus tree does not require irrigation but still provides a high yield, which results in many environmental benefits. The fiber is produced in a closed-loop process, where more than 99% of the water and solvents can be reused. Lyocell is the name of the fiber, and TENCEL™ is the trademark owned by the company Lenzing Fiber, but they are the same.

FSC Viscose and Triacetate

Viscose and triacetate are materials that come from wood cellulose after chemical processing. That’s why we call them artificial fiber as Tencel and lyocell. FSC is a certification based on the sustainable production of wood (from which cellulose is extracted), via the responsible management of forest resources. The origin of the cellulose is thus traced from the forest to the product.

ECOVERO is the most sustainable viscose at the moment. It is made exclusively from sustainably certified raw materials such as sustainable wood with the Forest Stewardship Council® or Pan Forest European Certification. The manufacture of this Lenzing EcoVero fiber is carried out with the greatest transparency and complete traceability at every stage of the production process, making it possible to identify the raw material in the finished product.

Denim

Eco-wash denim is a method savings up to 95% water, 50% chemicals and 80% of energy.

By reducing washing, drying process and the temperatures, using chemicals with lower environmental impact and by recycling steam and water you can already be more sustainable. But with eco-wash you create washed look over denim by laser; you can create bleached effect by wet ozone process and use less water by nano-bubble technology.

Eco-Wash chemicals don’t contain heavy metals and don’t use pumice Stones because of the muds its generates, the environmental impact and tear of machinery.

Eco-wash denim is highly bio-degradable and a product with low toxicity.

Jeanologia is a technique that brings to you the most advanced laser and eco technologies for fabric and garment finishing. Sustainable and efficient, it guarantees big amounts of water, energy and chemical savings. This pollution-free and disruptive technology eliminate manual and harmful processes for the worker’s health.

These are the two techniques most mentioned by brands.

Orange fiber

Orange Fiber is an innovative fabric made from tons of citrus waste from the juice industry. It is a silk-like cellulose yarn that can blend with other materials. When used in its purest form, the resulting 100% citrus textile features a soft and silky hand-feel, lightweight, and can be opaque or shiny according to production needs. It is used by the luxury firm as Salvatore Ferragamo to H&M Conscious, a premium collection made only with recycled and sustainable materials.

Piñatex

Piñatex® is an innovative textile that was developed for use as a sustainable alternative to both mass-produced leather and polluting synthetic materials.

The leaves are the byproduct of existing agriculture, and their use creates an additional income stream for farming communities. Piñatex® is a natural, sustainably-sourced, cruelty free material.

Apple leather

With the cores and skins discarded from the industrial food industry, apples are puréed, spread on a solid sheet, and dehydrated until almost all of the moisture has been removed. This purée turns into a flexible, leathery sheet that is cellulose-based featuring a variety of textures, thicknesses and can be embossed or laser printed. This material is mixed with PU to create a very durable and eco-friendly vegan leather.

One of the best known suppliers is Frumat. It is an Italian company, originating from Tyrol, one of the world’s leading apple producing regions.

Fish leather by ICTYOS

ICTYOS is an innovative ecological tannery that produces high-quality marine leathers in an ethical approach, using fish skins from the food industry and initially destined for destruction. Made from high-quality metal-free vegetable tanning, the leathers are made according to environmentally friendly manufacturing processes. They benefit from high resistance, a rare suppleness, a unique grain, and a homogeneous colouring that enhances the creations.

SQUAMA® is a salmon leather with unique properties that are unrivaled in terrestrial leather. Very resistant, flexible, and elastic, it is also durable and hypoallergenic.

STURGEON LEATHER is called the caviar of leathers. It represents a real alternative to conventional exotic leathers. It is the only leather in the world that posses spicules.

CARP LEATHER thicker than the Squama®, this leather opens new perspectives of creation in a lot of areas. Only coming from french sustainable caviar producers.

Certifications

GOTS or OCS is the most complete certification in terms of production that ensures that from the production of the raw materials to the production of the finished article, the production processes used are socially responsible and environmentally friendly. This standard covers all stages in the production of a textile article: processing, packaging, labelling, export, import and distribution of natural fiber products.

GRS (GLOBAL RECYCLED STANDARD) certification enables the recycled material to be strictly checked. This means it can be traced all the way to the finished product. Last but not least it ensures best practices in environmental practices, chemical management, and company management.

BCI COTTON (Better Cotton Initiative) is the world’s largest cotton sustainability program, which promotes better standards and practices in cotton farming and production and offers training to over two million cotton farmers throughout more than 20 countries. BCI cotton reduces the environmental impact of cotton production, while also improving the livelihoods of cotton farmers and economic development in cotton-producing areas.

FSC certification promotes responsible forest management worldwide. Products from FSC-certified forests are controlled from their origin, throughout the manufacturing process and up to their distribution. The FSC label is a guarantee that the products used come from controlled and responsibly harvested resources.

EU EUCOLABEL LYOCELL certifies that during the process of converting cellulose into fibers, the chemicals are applied in a closed circuit and processed. Exposure to chemicals is thus limited and strictly monitored.

RWS label (Responsible Wool Standard) is a voluntary global standard that addresses the welfare of sheep and of the land they graze on. It demonstrates farmers best practices and a means for brands and consumers to have the certainty that the wool products they buy and sell are in line with their values.

OEKO-TEX guarantees in a simple and standardized way to the consumers that they are buying a product that is not harmful to health or skin. The product may thus contain no harmful substances or in minimum quantity that do not represent any danger. Tests are carried out on more than 300 substances but also on PH, stability, and colorfastness. An Oeko-Tex certified product is not necessarily environmentally friendly or organic.

Brands to watch

Gucci-Off The Grind

Gucci Off The Grid is the first collection of Gucci Circular Lines and promotes the recycling of materials and fabrics, allowing you to minimize the use of new raw materials and waste less. The collection includes accessories, ready-to-wear, and travel items that are made from recycled, regenerated, organic, renewable raw materials, and sustainable sources. The main material in the collection is, ECONYL® regenerated nylon made from 100% pre and post-consumer nylon waste including abandoned fishing nets and discarded carpets…To support a virtuous up-cycling system, ECONYL® waste is recovered from Gucci Off The Grid production and then recycled to create new ECONYL® materials. Leather waste from the collection is also reused through our Gucci-Up program. Gucci Off The Grid collection leather is produced through a metal-free or chrome-free tanning process; Other elements are made from recycled materials and more sustainable alternatives, such as recycled polyester thread and lining; recycled brass, gold and palladium metal trim coatings, and solvent-free adhesives.

Marine Serre

The French designer MARINE SERRE question is: “Why does the world need another fashion brand?” demanding the industry to be more conscious of the world around it and on the impact that clothes have on the environment. Marine Serre’s line is made from about 50 percent up-cycled materials, patching pieces together, embroidering them, mixing jeans with puffy lace tops. The Regenerated Crochet Pull, made from old crochet table cloths, was one of the most artisanal highlights of the Marée Noire SS20 show. The designer thinks it’s quite a challenge to transform old things into “regenerated” garments, starting the process with research in dead-stocks or second-hand stores, searching materials and fabrics that fit with the idea of the collection.

Green Influencers

More and more influencers are trying to spread environmental awareness messages through their accounts, showing the most ethical and sustainable alternatives regarding lifestyle, food, and fashion. Social media is once again proving to be one of the most immediate vehicles to spread positive messages about sustainable fashion. Eco-influencers are a growing reality, influencing the consumers choices by giving space to innovative brands that stand out for their sustainable and ethical values.

Mira Duma, the first fashion influencer who turn to sustainable fashion, is undoubtedly standing out. She founded Future Tech Lab (FTL), a 2.4T$ organization with the mission to transform and empower fashion and apparel industry by improving its social and environmental footprint and to support the growth of fashion tech and sustainable fashion.

And what about designers ?

In the design and development phase, brands can reduce lifecycle impacts by considering the footprint of proposed garments upfront. Designs, especially the choice of raw materials, determine much of a garment’s destiny and impact. The fiber mix of a garment can impede or facilitate recycling, while the colors and prints will limit the options for dyes and process chemicals. With a full understanding of the implications of their decisions, they can adjust their designs to lighten the load for the entire production process.

Indeed, some leading brands have made headlines with more sustainable designs. Nike has “designed out” waste from the start with its FlyKnit collection of footwear, whose one-piece upper avoids multiple stitched or glued panels, cutting waste volume during production by 60%.

Adidas released athletic shoes under their ‘No Dye’ design principles, using materials in their natural ‘greige’ colour to avoid water or chemical use due to dyeing.

But the industry would still benefit from universal design standards discouraging fiber combinations that pollute, harm, or consume excessive resources. Designer can design and choose manufacturing techniques that are less polluting or create less waste. Including this process and this new way of thinking fashion design, can raise awareness in designers of their role and their collective impact.

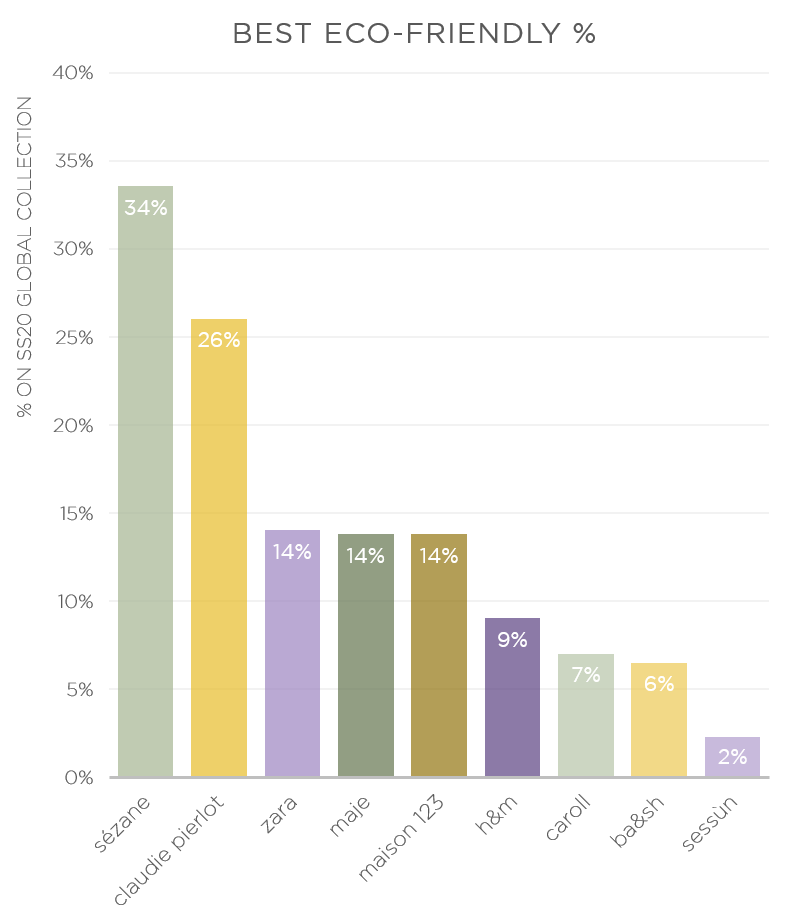

Sustainable Benchmarking

We decide to analyse the French market, that is very sensible to this subjet and we found the best brands that are investing themselves toward sustainability.

DNVB are the most farsighted. Having a more agile structure, they invested early and were able to react more quickly. Brands such as Balzac and Sézane are certainly examples to follow.

At Balzac the sustainable commitment starts with the desire to build a lasting fashion and moves from raw materials, recycling, local production to ethical engagement. At Balzac every piece of fabric is used. As an advocate of zero waste, rather than throwing away or destroying fabric stocks, as most brands do, Balzac recycles them into new collections: the “Collections Responsables”. These are basics products, cut from fabrics that other brands would have discarded and sold at a reduced price. Through partnerships, Balzac also helps other brands to recycle their fabrics, a first for the fashion industry.

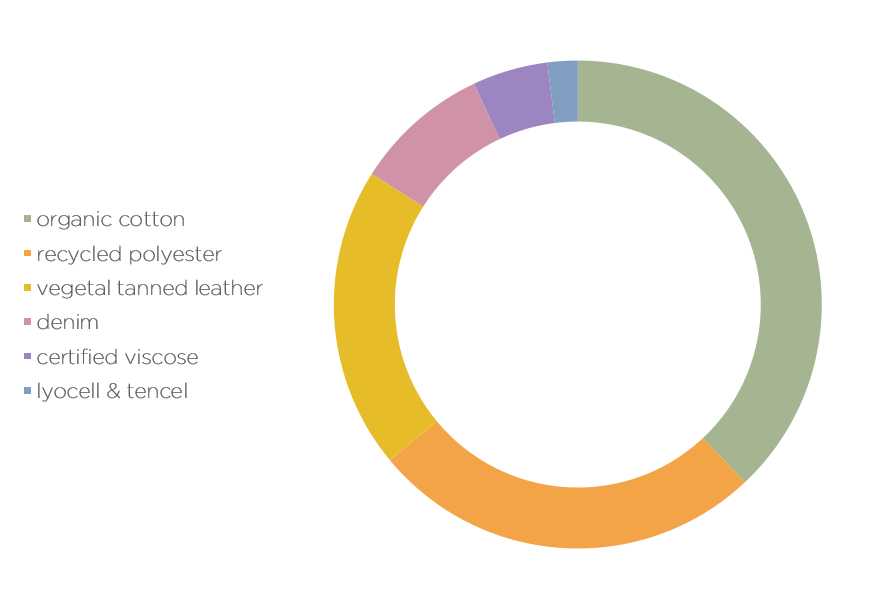

At Sézane, the share of eco-responsible materials has increased sevenfold in 36 months. The brand already has 70% of eco-responsible materials, 3 certifications (GOTS, Oeko-Tex, FSC®), 2 eco-friendly collections (sport and denim) and more than 12,000 recycled products. Not forgetting the DEMAIN solidarity program that supports dozens of associations and thousands of children.

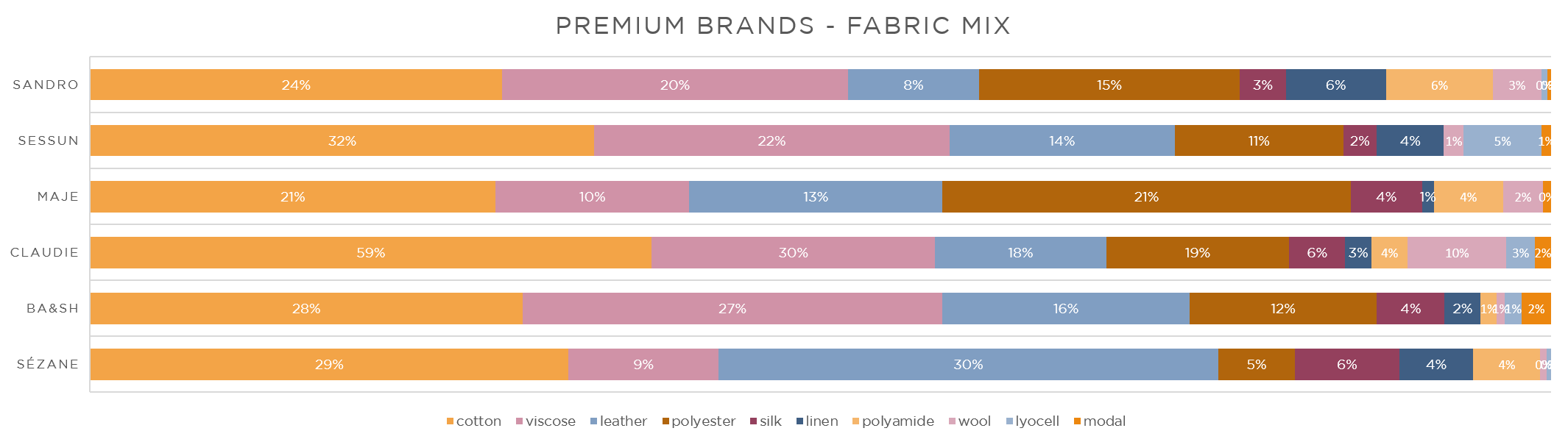

The Premium market has so much to do to get the right direction for sustainability. The most engaged in the French market are Claudie Pierlot and Maje, from SMCP group that are making an evolution in their fabrics and supply chain to be more and more eco-friendly.

Claudie Pierlot is offering a large sustainable offer, 26% of entire collection, labelling this products Claudie Cares. Maje has start with First Stone Collection that today represents 7 denim pieces. At Maje, Spring/Summer 2020 Collection presents 100% Eco-wash denim, 70% of the t-shirts are made by Organic cotton, 5% of the collection is made by FSC or EcoVero viscose, 5% of Recycled polyester.

Sessun has just made a few moves: 55% of their products are composed of natural materials, 1/3 of viscose is certified, just 8% of products are made in 100% synthetic and 1/3 of leather products are made from vegetable tanned leather. But as we have seen before in this report, using natural fibers is not a green solution for real.

We can say that this is a shy start for premium market, but this brand are certainly distinguishing from other players that haven’t seen sustainability as a priority so far. And we can say that these ones are quite a lot even in a sensible market as France. Just half of the brands representing the French premium fashion are talking about they sustainable strategies and goals.

French Middle market seems to be more engaged. Brands to notice are Maison 123 from Etam Group and Caroll. They are also boosting their sustainable offer. Caroll is committed to more responsible fashion, with its Eco-Friendly capsule. This new capsule features fabrics from organic farming, traceable and certified natural materials from TENCEL™ Lyocell or viscose ECOVERO™. Each of the factories in charge of these products is audited.

Since 2018, Maison 123 has been using more environmentally friendly materials (organic or recycled) to produce part of the collection, the aim being to extend their use to as many products as possible. 14% of our Spring-Summer 2020 collection is environmentally friendly. All Maison 123 stores have a recycling point and their engagement is including local manufacturing, transparency, traceability and solidarity.

Of course, big Fast Fashion companies as Zara and H&M are paying more attention to sustainability, also because they are the biggest producer of garment of the planet. The data shows that famously these criticized fast fashion brands are actually making more effort than others to preserve our planet. Indeed, Zara and H&M have been looking for more sustainable options for several years.

Zara starts the “Join Life” collection in 2016 and today it accounts for 25% of its assortment. They signed the fashion pact and made a concrete commitment to sustainability with very strict undertakings for 2025. Zara promotes recycling in all phases of the product’s life cycle, using more environmentally friendly materials, to reduce water, CO2 and plastic consumption. And, of course, Zara is socially and ethically committed to the well-being of its workers and suppliers.

H&M’s sustainable goal is for all products to be made from recycled materials or from sustainable sources by 2030. H&M already states that this is the case for 57% of the materials they use. H&M is trying to close the loop in the product life cycle with its clothing collection program, which is the largest program of its kind in the world. It was launched in 2013.

Although H&M won the first place this year with an index of 70% from the Fashion Revolution, its “Conscious” collection only accounts for less than 10% of the total assortment. These pieces are made with at least 50% materials from sustainable sources, such as organic cotton and recycled polyester. The only exception is recycled cotton, which accounts for a maximum of 20% to guarantee the quality of the product. H&M is engaged promoting innovation through companies such as Re:newcell, Worn Again, Ambercycle and Infinite Fiber. The Global Change Award, launched by the H&M Foundation, this year honoured Vegea™, a vegan leather made from grape waste, used in the Conscious Exclusive Spring 2020 collection, and Circulose®. Powered by renewable energies, without virgin cotton, trees or oil, it is better than ever: Circulose® removes carbon dioxide from the environment and prevents deforestation to cultivate cotton fields.

So, part of the market is definitely moving and mobilizing towards sustainability. The topic is very broad and the goal very ambitious. But for countless reasons, and for reasons that are not only ecological, changes need to be made now. We need to be aware of the damage that the fashion industry does and that there are solutions to do better.

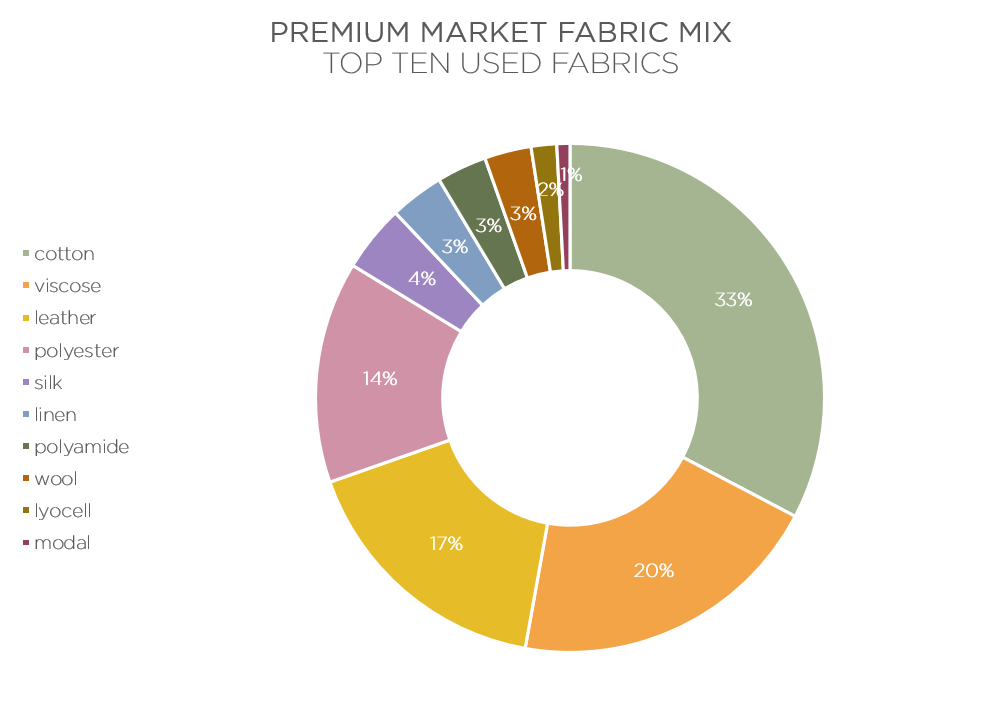

Most used sustainable fabrics

Of course, it is important to know which fibers are used the most and on which your competitors and the best eco-friendly brands are working on.

The most used fabrics in the mass market industry for SS20 is cotton, followed by polyester and then viscose. The trend is more or less similar in the Premium fashion with cotton as the most used fabric, followed by viscose, leather and polyester. Few year ago, polyester was the main fabric, and viscose has raised to become the first fiber next to cottons and other artificial fibers.

Globally, polyester is resented by the customer as a cheap fiber, but its practicality in washing and ironing, makes up for this. Now that the ecological conscience is getting stronger and stronger in the customer, polyester is considered the most polluting fiber, therefore more criticized. In summer, artificial fibres such as viscose, tencel and lyocell are certainly preferred to polyester. While in winter, polyester regains relevance.

The biggest problem with recycled fibers is that the quality is not yet at a high level and that the use of these materials requires caution and numerous tests. Certainly quality is important for the durability of the products, which is one of the first requirements of an eco-friendly product, but using recycled fibres does not guarantee the stability of the fabrics after repeated washing. So choices must be made carefully.

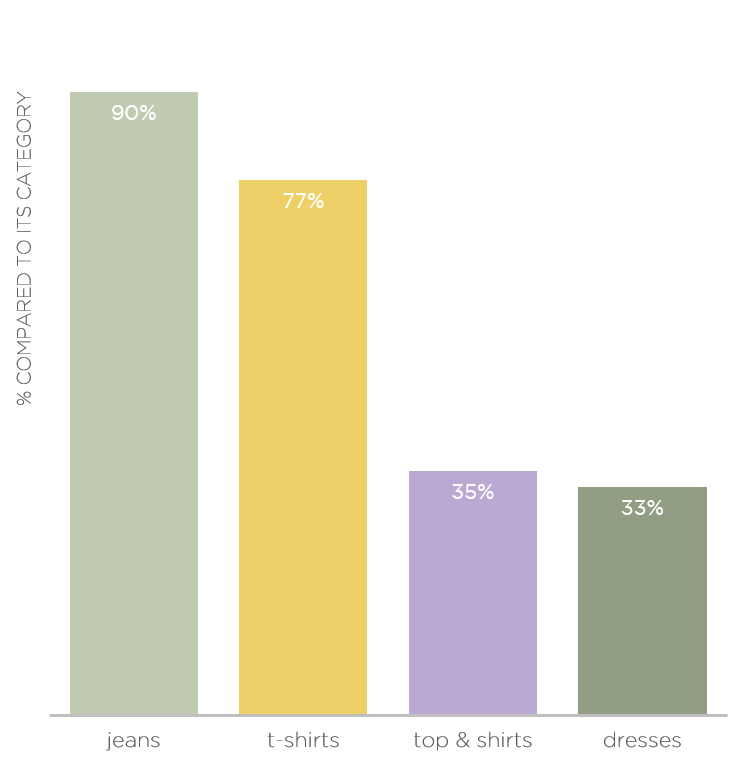

Top sustainable categories

To take the first steps towards a sustainable collection, it is important to define its values, to know the different possibilities and certifications, but also to let oneself be guided by the precursors who today set an example for other brands but also for consumers. It is not always easy to make the difference between marketing and therefore the declarative and the real commitment. Thanks to the continuous analysis of the collections, Livetrend detects all the information of the products and makes it possible to identify eco-friendly products.

This chart shows which categories have the highest percentage of sustainable products. So first the brands have focused on denim and how to produce it in a way that saves as much water as possible. Indeed, these innovative methods have been under study for several years and are now a reality with several suppliers.

Secondly, the brands have tackled cotton. Which is one of the less sustainable fibers in its production. So clearly the second most impacted category is the t-shirts. The use of organic cotton, of course, but also an increase in linen and fibers such as FSC viscose, lyocell and tencell. A drastic decrease in the presence of polyester in this product range, even for mass market players.

After these two major categories, tops and dresses are now coming with an average of 34% of sustainable products. Indeed, often the same material is used for tops and dresses.

For the summer, FSC viscose, lyocell and tencell, together with cottons and linens, push the eco-friendly percentage up to 30-35% even for brands new to sustainable topics. For winter, such fibers will surely be less suitable. Certified and recycled wools will become more important as well as recycled polyesters.

An Industry in full Transformation

New business models are raising and new brands are including sustainability in their principal values. Established brands are adapting and introducing new products but also new strategies. Circular economy is a strong subjet. In fact the better way to be eco-friendly is to not produce at all. Of course this is not an option for the fashion business.

The growing awareness of the industry and the consumer is so strong that it is leading to new models and we see that brands are testing rental, second hand, recycling, social and ethical commitment. They are trying to limit the CO2 footprint of the company and to raise awareness among their employees, but also among their consumers. In fact, for the pollution produced by clothing, the industry is 60% responsible, the end consumer 40%. Brands therefore sensitize their consumers to wear their garments several times, to wash them with detergents that are not aggressive for the environment, to recycle, donate or resell their garments.

In addition, the coronavirus crisis has pushed and accelerated some trends already underway. Nearshore production has become a reality for many brands, you can have a look to 1083 a denim brand that was born as a challenge: to relocate the production of jeans less than 1083 km from the final destination reducing costs and emissions due to decentralized production and encouraging the creation of local employment.

On-demand production, which allows you to produce only what the customer requires, rather than producing bulky amounts of stock, is coming back as a business model for DNVB. Have a look at Asphalte, a french menswear brand.

Even the fact of paying the right price for the product is a mentality that has installed itself in the consumer and today an eco-sustainable product does not cost more than a classic product.

Sustainability requires a great commitment and a change of mentality and methodology. It must be brought by managers as well as employees, who must be made aware in their daily actions and in the impact their work has on the desired results.

Definitively, sustainable is a great opportunity to act differently and change the world.